|

|

#Cone Dy #Cone Dy |

|

COMPLETE CONE DYEING PLANT FOR COTTON AND POLESTER CONES

STILL INSTALLED AND IN RUNNING CONDITION .

The following is the description of the machinery yarn dyeing plant to sell:

The capacity is approx. 15 tons per day on Polyester or

approx. 10 tons per day on cotton resp. 18 tons per day on acrylic.

Dyeing machines: Horizontal pressurized machines for bleaching/dyeing of packages:

1.FLAINOX ATR/OR/HT 100KGS............

2.FLAINOX ATR/OR/HT 250KGS............

3.FLAINOX ATR/OR/HT 600KGS............

4.FLAINOX ATR/OR/HT 600KGS............

5.FLAINOX ATR/OR/HT 600KGS............

6.FLAINOX ATR/OR/HT 600KGS............

7.FLAINOX ATR/OR/HT 600KGS............

8.FLAINOX ATR/OR/HT 600KGS............

with 53 carriers.

* N.B: the dyeing machines 3/4 - 5/6 - 7/8 can work matched and dye 1200kgs.

CIRCULATION PUMPS: controlled by inverter, they are bi-directional turbo-propeller axial pumps. They are reversible, changing direction automatically with that of the motor and therefore does not require a reversing valve.

Other machines:

10. Manual binding machine GALVANIN SBT...................................

11. Load cone robot GALVANIN RBT CRG.........................................

12. Automatic hydroeextractor DETTIN DT40………………………………..

13. Automatic hydroextractor GALVANIN RBT CSR............................

14.Dryer DETTIN AR22.75……………………………………………………………..

15.Dryer DETTIN AR22.75……………………………………………………………..

We are looking forward to sell the whole plant together. We further provide you with more details below pointing you out the advantages of the whole plant.

For inpsections , please give one week prior notice. The nearest Airport is Malpensa

Milan Italy

1.Space required 1000 square meter

2.Diameter of cones 22cm and also small cones 12cm

details given, Polyester cones big ones also can be loaded as per list

3.Total kw need 600 kw/h

4.THe boiler capacity they will provide. Steam boiler needed.

5.After hydroextracting, the Dryers are Air and steam heated Capacity 20 tons per

day polyester, in case of cotton 10 tons, acrylic 16 tons

6.No lab is there as they are still continuing the operation and keeping it. They will

give list , not so much of equipment is required

7.No cone winding as they were getting cones from clients for job work of Dyeing

8. The vessels being horizontal, pumps or any other maintenance is easy . Also the

machine efficiency is more

No loading cranes required

9- Note that Automatic trolley loading device is included which is simple and can

load full or half trolleys. This makes

it very fast and less man power

10. Unloading of trolley is also there . The Hydroextractors are in line with this kind

of automation

11. We can provide also technical assistance at extra cost. Flainox manufacturer is working company in the same area and are pioneers for good dyeing technology

|

|

#7760 |

|

Complete plant for pants manufacturing for sale

High quality pants making plant with stock of fabrics and machines.

There is a machines lot , fabric lot and ready made pants and accessories

We can make a total package

|

|

#7660 #7660 |

|

complete RIETER OPEN END plant OFFER:

n. 1 Carresi opener

year 1989

working width 2.000 mm

with suction device and fun

n. 1 Carresi mixing box

year 1989

size 4.000 mm

production 2.000 kg/hour

box capacity 5.000 kg

with suction devices and fun

n. 1 Carresi Beater

year 1989

working width 2.000 mm

production 2.000 kg/hour

with suction devices and fun

n. 1 Tecnomeccanica Biellese Oiling box

with suction devices and fun

n. 4 Marzoli carding machines

model CX300

year 1994

with double autolever

M & M System

Working width 1.000 mm

104 mobile combs + 5 fixed in enter + 5 fixed in exit

Drum O

With automatic doffing for cans size 16"

Production capacity 40 kg/hour each

n. 2 automatics feeder from silos to carding machines

with suction devices

n. 1 Open end spinning machine Rieter

model RU04

year 1989

192 rotors

Rotor diameter 56 mm

Cards OB20 for cotton

Card speed from 5.000 to 9.000 rpm

Rotor speed from 30.000 to 50.000 rpm

For count range from 5 to 20

With 1 complete set of rotor size 48 mm

n. 1 Open end spinning machine Rieter

model RU04

year 1995

192 rotors

Rotor diameter 56 mm

Cards OB20 for cotton

Card speed from 5.000 to 9.000 rpm

Rotor speed from 30.000 to 50.000 rpm

For count range from 5 to 20

With 1 complete set of rotor size 48 mm

Split sale possible

|

|

#7640 #7640 |

|

CARDING PLANT FOR SALE:

PREPARATION OF COLORING

1 BALE OPENER

1 CONDENSER

1 CARDS COSMATEX 1993

1 CONDENSER + FAN

1 TANK WITH OILING DEVICE FOR MIXTURE

2 FANS FOR ASPIRATION

1 CONDENSER

1 OVERHEAD TRAVELLING CRANE FOR MIXTURE SPREADING

2 BOX FOR MIXING

1 CUTTER FOR MIXING

5 DEVIATORS

VARIOUS TUBES

1 MULTIOPEN OPENER

CARDING

ASSORTMENTS 1

1 CARDING MACHINE OCTIR WITH DIAMETER CYLINDERS CM 1600 HL CM 2000

2 BOX FOR STORAGE

1 CUTTER FOR BOX STORAGE WITH AUTOMATIC CARDS LOADING

1 BOX LOADER WITH AUTOMATISMS

1 COMPUTERIZED ELECTRONIC LOADER OF 1995

1 LIMBER

1 CARD DIAMETER CM 1600 WITH STRIPPING AND WORKING DEVICES

1 COMBER OF DIAMETER CM 1500

1 CUTTING FRAME

1 TRAVERSER

1 CARD DIAMETER CM 1600 WITH STRIPPING AND WORKING DEVICES

1 COMBER OF DIAMETER CM 1500

1 CANVAS WITH CYLINDERS

1 CARD CYLINDER DIAMETER CM 1600 WITH STRIPPING AND WORKING DEVICES

1 COMBER OF DIAMETER CM 1500

1 PARTITION DIVISOR OF 11,89 MM WITH LACE,156 WIRES WITH 8 FALSE WIRES

1 TACKLE

STRINGY OPENER

ASSORTMENTS 2

1 CARDING MACHINE OCTIR WITH DIAMETER CYLINDERS CM 1600 HL CM 2000

2 BOX FOR STORAGE

1 CUTTER FOR BOX STORAGE WITH AUTOMATIC CARDS LOADING

1 BOX LOADER WITH AUTOMATISMS

1 COMPUTERIZED ELECTRONIC LOADER OF 1995

1 LIMBER

1 CARD DIAMETER CM 1600 WITH STRIPPING AND WORKING DEVICES

1 COMBER OF DIAMETER CM 1500

1 CUTTING FRAME

1 TRAVERSER

1 CARD DIAMETER CM 1600 WITH STRIPPING AND WORKING DEVICES

1 COMBER OF DIAMETER CM 1500

1 CANVAS WITH CYLINDERS

1 CARD CYLINDER DIAMETER CM 1600 WITH STRIPPING AND WORKING DEVICES

1 COMBER OF DIAMETER CM 1500

1 PARTITION DIVISOR OF 11,89 MM WITH LACE, 156 WIRES WITH 8 FALSE WIRES

1 TACKLE

STRINGY OPENER

ASSORTMENTS 3

1 CARDING MACHINE OCTIR WITH DIAMETER CYLINDERS CM 2000 HL CM 2500

2 BOX FOR STORAGE

1 CUTTER FOR BOX STORAGE WITH AUTOMATIC CARDS LOADING

1 BOX LOADER WITH AUTOMATISMS

1 COMPUTERIZED ELECTRONIC LOADER

1 LIMBER

1 CARD DIAMETER CM 1775 WITH STRIPPING AND WORKING DEVICES

1 COMBER OF DIAMETER CM 1500

1 CUTTING FRAME

1 TRAVERSER

1 CARD DIAMETER CM 2000 WITH STRIPPING AND WORKING DEVICES

1 COMBER OF DIAMETER CM 1500

1 CANVAS WITH CYLINDERS

1 CARD CYLINDER DIAMETER CM 2000 WITH STRIPPING AND WORKING DEVICES

1 COMBER OF DIAMETER CM 1500

1 PARTITION DIVISOR OF 10,5 MM WITH LACE, 208 WIRES WITH 8 FALSE WIRES

1 TACKLE

STRINGY OPENER

ASSORTMENTS 4

1 CARDING MACHINE OCTIR WITH DIAMETER CYLINDERS CM 2000 HL CM 2500

2 BOX FOR STORAGE

1 CUTTER FOR BOX STORAGE WITH AUTOMATIC CARDS LOADING

1 BOX LOADER WITH AUTOMATISMS

1 COMPUTERIZED ELECTRONIC LOADER

1 LIMBER

1 CARD DIAMETER CM 1775 WITH STRIPPING AND WORKING DEVICES

1 COMBER OF DIAMETER CM 1500

1 CUTTING FRAME

1 TRAVERSER

1 CARD DIAMETER CM 2000 WITH STRIPPING AND WORKING DEVICES

1 COMBER OF DIAMETER CM 1500

1 CANVAS WITH CYLINDERS

1 CARD CYLINDER DIAMETER CM 2000 WITH STRIPPING AND WORKING DEVICES

1 COMBER OF DIAMETER CM 1500

1 PARTITION DIVISOR OF 9,5 MM WITH LACE, 240 WIRES WITH 8 FALSE WIRES

1 TACKLE

STRINGY OPENER

CARDING ACCESSORIES

6

3 BENCHES FOR GRINDING

2 GRINDER

2 TROLLEY FOR TOOLS

6 TROLLEYS FOR LEVATA CANNELLE

4 TROLLEYS PORTA CANNELLE VUOTE

2 ASPIRATOR CFM

1 SCALE

5 TROLLEYS WITH SUPPORTS FOR WORKERS

1 SCALE WITH 2 RAMPS

DRILLER FOR CLEANING AND VARIOUS ACCESORIES

OIL CHANGER

VARIOUS FITTINGS (Caipo cont. Tit - A.E.Z. Alfa Panel cont. Prod. Carde)

AUTOMATIC CLEANING

PUMP HP 50 PER ASPIRATE AND CLEAN THE CARDS GASKETS

VARIOUS TUBES

VARIOUS ACCESSORIES

SACKS FOR DUST

SPINNING DEPARTMENT

1 RING GAUDINO FST YEAR 1975 DIAM. RING 65 SPINDLES 256

1 RING GAUDINO FST YEAR 1975 DIAM. RING 65 SPINDLES 256

1 RING GAUDINO FB YEAR 1987 DIAM. RING 75 SPINDLES 240

1 RING GAUDINO FB YEAR 1987 DIAM. RING 75 SPINDLES 240

1 RING GAUDINO FST YEAR 1975 DIAM. RING 65 SPINDLES 240

1 RING GAUDINO MODEL FB WITH AUT. LIFTER YEAR 2007 DIAM. RING 75 SPINDLES 308

1 RING GAUDINO MODEL FB WITH AUT.LIFTER YEAR 2007 DIAM. RING 75 SPINDLES 308

DUST INSPIRATOR

1 DUST INSPIRATOR FOR YARNS 1-2-3

|

|

#7560 #7560 |

|

Prepration line composed by:

1 Rebreaking 1 steaming and stretching machine Seydel - year 1988 - model 679

1 re-stretcher NSC Schlumberger R5L 10/GC 13 Type 57 – year 1989

1 gill NSC - GC 13 CPA - with autolever – year 1988

1 gill S. Andrea SH 22 with autoleveler, output 2 slivers – year 1988

1 gill S. Andrea SH 24, output 4 slivers – year 1988

1 vertical finisher NSC Shlumberger FMV 30 - 20 bobbins with auto-doffer – year 1987

Spinning department composed by:

2 spinning frames ZINSER model 421E – Year 1994 - 580 spindles each – ring rail diameter 51 mm – gauge 82,5 mm

Linked n. 2 coner mcs Schlafhorst Autoconer – model 238 – year 1994 – 20 spindles each – electronic clearer Uster D4 – System

2 spinning frames ZINSER model 421E1 – Year 1995 - 580 spindles each – ring rail diameter 51 mm – gauge 82,5 mm

Linked n. 2 coner mcs Schlafhorst Autoconer – model 238 – year 1995 – 20 spindles each – electronic clearer Uster Polymatic – System

|

|

#43642 |

|

USED RIG EXCELLENT IN WORKING

CASA GRANDE

MODEL Klemm KR 804-1

1993

10,000 Hours

Equipped with KD1011 drifter

5.6m long mast attached

2.3m track width

4000mm stroke

Double clamped

14,000kg operating weight

CE Marked

|

|

#43599 #43599 |

|

OFFER 43.599

NO. 12 TSUDAKOMA AIR JET LOOMS MODEL ZAX

width 210 cm, year 2000-2001,

4 colors

with Electronic dobby Staubli 2871 16 levers year 2000-2001,

with:

12 heald frames,

1.5 beam,

1.5 cloth roll,

4 weft feeders with creel

5.000 heddles and droppers.

|

|

#43592 #43592 |

|

Offer No 43592

Excellent working Benninger Sectional warping

on sale

No 1 Sectional warping Benninger On sale

Make Benninger Model Ergotronics

year 2003

Width 2200mm

Cone Length, Conicity 1:8

With waxing

With Pressing Roller

Beam exit dia 800

Creel Benninger Ben Guard with 320 cones

|

|

#43585 #43585 |

|

Offer No 43585

NO. 03. Drawing machine Sant’Andrea Novara Mod. CSN

year 1995

Chain head

feeding creel for cans

Automatic delivery 1 sliver 1 can working

Can size 800 x 1000 ,

With one can in ready for doff

Machine reconditioned for all parts

excellent condition

|

|

#43583 #43583 |

|

OFFER NO 43583

NO 1 ALMETER AL100 COMPLETE WITH PREPARATORY ELEMENT OF FIBROLINER FL 100

MODEL COMPLETE FROM A LAB

YEAR 1999

WORKING MODEL , WITH COMPUTER FOR DATA COLLECTION

SOFTWARE

CONVERTER

PC COMPUTER WITH MONITOR AND PRINTER

WE HAVE RECONDITIONED FOR RUNNING THIS DEVICE

|

|

#43.562 #43.562 |

|

NO. 1 Coating Machine Make Matex

Width 200cm , All electronic control

With Two chambers for Heat Drying

With Cylinders for cooling

working width of fabric 180cm

Coating Division 14 meters

Delivery on Batching or on Trolleys

Machine can coat PU or PVC for eco leather

on Paper or directly on fabric

Can be used as Resin applying machine

|

|

#43.545 #43.545 |

|

OFFER 43.545

NO. 4 PICANOL GAMMAX RAPIER LOOMS

Year : 2005

Working width : 2200mm

Each loom with:

Weft Colours (Max): 6

Accumulators: 3 to 6

Selvedge Jacquard: Eltex HS2000

Selvedge type: Tucking units

Dobby model & type: STAUBLI 2670

Installed levers: 16

Heald Frames: 10

Warp beams: 2

Cloth rollers: 2

Heald wires: As on Looms

Droppers: As on Looms

|

.jpg)

|

#43.276 #43.276 |

|

OFFER 43.276

NO. 3 SOMET rapier looms Mod. EXCEL,

working width 2100 mm,

years 2x1996 and 1x1997,

Staubli dobby 2660 20/16 shafts, 8 colors, GFG

NO. 1 SOMET rapier loom Mod. SUPER EXCEL,

working width 2100 mm, year 1999,

Staubli dobby 2668 20/16 shafts, 8 colors, GFG

Accessories to each loom :

2 warp beams

2 cloth rollers

12 heald frames

heddles and droppers as on the looms

The carters missing in the photos are available in the factory.

weft feeders :

1 loom with 5 LGL Sirio Robot

1 loom with 2 Roj Chrono + 2 Roj Dart

1 loom with 3 Roj Chrono + 1 IMP

1 loom with 4 LGL Sirio Robot

|

|

#43.222 #43.222 |

|

OFFER 43.222

No. 3 Tsudakoma Airjet Looms Model Zax

Width 230cm

Year 2000

With Electronic Stuabli Dobby model 2871

With 16 levers

with 4 weft colors

With Inverter

With Display

Machine equipped with

10 Heald frames

4 weft feeders

1 Weft Creel

1 Control Panel

Droppers and Heddles

1.5 beam each loom

1.5 cloth roll each loom

Machine still on mill floor

Immd decision required to Load

PRICE AND PHOTOS UPON REQUEST

|

|

#43.154 #43.154 |

|

Recovery of Lanolina :

Complete plant of Alfa Laval complete reconditioned.

We will provide full technical support and install in client Mill giving

Training and trail runs :

No 1 CENTRIFUGE ALFA LAVAL

Fully Recondtioned

Year 1984

Max speed rpm 5.000

Weight 1.300 kgs

Diameter rotor 368 mm

Motor: 11 kw

1.460 rpm

380 V 50 Hz

10/17,5 A

Working in Tandem with the finisher plant as below

REF. B11

N. 1 FINISHER EXTRACTOR ALFA LAVAL

YEAR 1987

Motor: 5,5 kw

1.450 rpm

380 V 50 Hz

Full set complete with Electrical Panel

Alfa-Laval equipment for Lanolin extracting contains following machinery:

- New Netsche feeding pump with velocity regulatorself cleaning bolter with automatic mechanism for slam sink

- Reconditioned centrifugal Ceramic separator

- Reconditioned heat exchanger with temperature regulator P 14 HB

- centrifugal pumps

- Electrical new panel with 3 inverters

|

|

#43.121 #43.121 |

|

No. 01 small wool washing line

Make: Fleissner-Grutech

- Working with 120cm and Rahwoolcapacity for 0.5% residuefat is 100kg/h or around 200kg/h for higher residuefat.

- can run with bigbales up to around 300kg or with open woolflakes.

- can be erected in compound: Simultan washing and drying

(lenght around 30m and 55KW)

The wet line (Pos. 2) can be sold also single.

The rostfree trougs from

Cabinplant Denmark are with pneumatic press and programcontrolling.

|

|

#43.087 #43.087 |

|

OFFER 43.087

CASHMERE FIBRE SPINNING

Pleased to offer

Complete cashmere spinning plant making 100%

cashmere fibre with system of mule spinning to make

cashmere 100% yarn for sweaters and pullover garments .

Its running and we will give installed and running .

Working on cashier fibre length 30 tp 45mm

count Nm 1/28 to 1/36 knitted yarn

No. 4 cards

Make: Tatham 2part 2 part

Complete with Cliffe hoppers

4 - 150 good ends…..9.3mm series tapes

yarn count: yorkshire skein 75 - 24 and 70 - 16

All great conditions

some recently recovered

No. 01 Bigagli B6 mules

years: 1991 / 1992 / 1995

1 - 16x 29 ends

No. 01 Twisting machines Two for one twisters

Make: Volkmann 08

120 spindles

No. 01 Autoconer Automatic Cone winding machine

Make: Sclafhorst 238 40 spindles

|

|

#43.042 |

|

No. 08 Preowned Rapier Looms

Make Picanol

Model Gammax 8 R

Year 2004

Width 190 cm

With Electronic Staubli Dobby model 2670 with 20 levers all installed

With 8 colors

With electronic take and let off

With accessories

16 frames

4 weft Feeders

1.5 warp Beam

1.5 cloth roll

5000 droppers and Heddles

380v 50hz

|

|

#43.041 |

|

No 08 Preowned Airjet Looms

Make Dornier

Model LWV 8/S

Year 1999

Width: 200 cm

With Electronic dobby Staubli model 2871 with 16 levers all installed

8 color

Each machine equipped with:

2 weft feeders

1.5 beam

1.5 cloth roll

12 heald frames

1 creel

1 warp stop motion

5000 droppers and heddles

380v 50hz

|

|

#43.024 |

|

AIRJET LOOMS SOMET ON SALE

COMPLETE PLANT:

No. 21 Airjet looms

Make: Somet

Model: Clipper

Year: 1997/98

Width: 210 cm

With Staubli Dobby 16 levers

4 colors

12 frames

1.5 beams

1.5 cloth roll

with inverter

No. 02 Airjet looms

Make: Somet

Model: Mythos

Year: 2001

Width: 230 cm

With Staubli Dobby 16 levers

4 colors

12 frames

1.5 beams

1.5 cloth roll

with inverter

with compressor

|

|

#43.017 #43.017 |

|

LABEL NEEDLE WEAVING MACHINES ON SALE

NO. 03 MULLER MACHINES

MODEL: MVC

YEAR: 1988

WITH HARNESS

JACQUARD

WITH ELECTRONIC PROGRAMMING

MACHINE RUNNING

COMPLETE

TAFFETTA HARNESS ON TWO MACHINES

ONE WITH SATIN HARNESS

MAKING LABELS

|

|

#43.013 #43.013 |

|

01 Automatic Cone to Cone winding machines

Make: Murata Mach coner

Models : 7-v

40 heads

Year !998

Machine working

01 machine with stribbie Peyer PI 551

with splicer Murata Z 21

Waxing device

01 Trolley

Exit 6” 4°20’

Automatic Feeding of Cones with four Lots

Auto Doff

|

|

#43.005 |

|

Complete Testing Labrotary for wool

on sale now with us ready for delivery

01 Uster Tester 3

Product code: Lab 150

Make: Uster

Model: Tester UT3

Year: 1995

Modules: YC creel - EC42 sensor H (hairiness)

ec5 sensor D - sensor B - absorber B -

SP signal processor – printer – stabilizer –

colour / trash module

01 Dynomometer Tensile strength Tester

Make Brustio

Model ADF SER 1097

Caldera Bossi

With PC monitor and Printer and keyboard

01 MESDAN LAB

A device for Testing Moisture Complete with weighing scale, monitor,

printer keyborad

01 Sample Carding Machine with Protection

Lab Carding Machine For making sample sliver

01 Nep Counter

Magnifying lens foEP counter

with multiple counters numeric

01 Microsope

Make Poland Model MP3. Resolution

Fibre Microscope for fibre analysis

01Twist Tester

Electric Torsion Tester Make Branca for ply yarn

01Twist Tester

Electric Torsion Tester Make Omac Biella

01Yarn Board maker

Planofil Make Branca for yarn irregularities on Black board

01 Reeling Machine

Manual Yarn Reel Make Branca complete

with electronic weighing scale for yarn count

01 Melange Color Tester

Motorized felt melange maker for color shade verification

01 High Resolution Microscope

Make Caldera Bossi 3 lens High resolution

01 Lab Dyeing device Make Maino Inox

Temp control , Inox

01 Yarn Fineness Tester

Micronair tester Make SPINLAB

complete with small compressor

01 Humidity tester For yarn

Electronic humidity tester with Meter and table

01 Knitting Machine For Lab

Small cylinder dia for knitting sample maker

for lab Italian make

01 Fabric Strength Testing Dynamometer

Strenngth tester Branca Complete

|

|

#42.986 #42.986 |

|

NO. 07 RIBBON WEAVING MACHINES

MAKE: TEXNOVO

MODEL: 6X30 (2 MCS) 5X30 (4 MCS) 4X40 (1 MC)

|

|

#42.934 #42.934 |

|

NO. 03 SECOND HAND WEAVING LOOMS

MAKE: VAMATEX

MODEL: C401-S

YEAR: 1987

WITH Jacquard Bonas CSJ 1200

WIDTH 190 cm

EACH MACHINE EQUIPPED WITH:

6 HEALD FRAMES

3 WEFT ACCUMULATORS

2 WARP BEAMS

2 CLOTH ROLLers

5000 HEDDLES

5000 DROPPER

|

|

#42.932 |

|

NO. 01 SECTIONAL WARPER

MAKE: COMAT

MODEL: SF

working width: 220 cm

control panel

automatic electronic creel double feeding

with beaming device

cooling breaks device

motor 9+25 hp

with 02 remote controls

|

|

#42.931 |

|

NO. 01 AUTOMATIC SECTIONAL WARPING MACHINE

MAKE: SUZUKI

MODEL: SW-K7A

year: 2001

width: 225 cm

electronic let off and take up

control panel

tension control device on let off

with beaming device diam. max 1000 mm

with beaming motor 7,5 KW

|

|

#42.925 |

|

NO. 02 SECOND HAND WEAVING LOOMS

MAKE: SULZER

MODEL: G6200

WIDTH: 220 CM

YEAR: 1X1997 1X2000,

WITH DOBBY STAUBLI 2670, 20 SHAFTS,

INVERTER INCLUDED (ONLY ON ONE LOOM),

8 COLORS

EACH MACHINE EQUIPPED WITH

04 FEEDERS WITH SMALL CREEL,

01 BEAM WITH FLANGE Ø 70/80 CM,

02 CLOTH ROLLERS,

12 HEALD FRAMES

5000 DROPPERS + HEDDLERS

380V 50HZ

|

|

#42.915 |

|

NO. 16 SECOND HAND WEAVING LOOMS

MAKE: SULZER

MODEL: G6300

WIDTH: 220 CM

YEARS: 2000, 2001

WITH ELECTRONIC DOBBY STAUBLI

4 WEFT FEEDERS IRO WITH CREEL

UP TO 8 COLORS INVERTER FOR SPEED CHANGE

BEAM MAX FLANGE 800

WARP STOP MOTION WITH 6 RANGES MAX

EACH MACHINE EQUIPPED WITH :

1,5 BEAMS

10 HEALD FRAMES

50000 HEDDLERS

50000 DROPPERS

02 CLOTH ROLLERS

|

|

#42.676 #42.676 |

|

24 DORNIER AIR JET LOOMS model LWV2/E, width 280 cm, year 1995, 2 colours, cam motion 8 lever

Looms equipped with 2 weft accumulators, leno device

3 DORNIER AIR JET LOOMS model LWV2/E, width 340 cm, year 1995, 2 colours, cam motion 8 levers

Looms equipped with 2 weft accumulators, leno device

|

.jpg)

|

#42.649 |

|

Complete plant for making Bed Mattress

On sale for immd purchase running complete small plant making Bed mattress both double and single size

Manual /automatic machines and located in 1000 sq meter area. Producing high quality product in cotton fabric, in springs or Memory.

Consisting of

No 1 Quilting Machine Make Due Effe

Year 2004

Quilting on Frames

TWo heads , one heavy

Size 200/300 cm

With a Preparatory Stand Model SM 310

No 1 Fabric Circular Cutter for Strips

No 1 Felt Bending and cutting machine for making

the box of the Mattress

No 1 Table for Inserting the Springs and box making

No 1 Various storage for Fabric or other material

No 1 Table with Border stiching Machine Pfaf.

moving with operator mounted platform

No 1 Press for Mattress Button insertion

No 3 Border Stiching machine for making the fabric covers

No 1 Handle insertion and preparation

No 2 Stitching machines

No 1 Machine for automatic preparation of Fabric strips

stitched in serial.

Other accessories

|

|

#42.376 |

|

No. 06 COMBING MACHINES

MAKE: SANT' ANDREA

MODEL P100

YEAR: 2000

CREEL FOR BOBBINS

CANS WITH 24 ENDS

EXIT WITH 1 SLIVER IN 1 CAN 1000 X 1200 MM

WITH STEAMING

WITH SUCTION DEVICE

COMPLETE

|

|

#42.229 #42.229 |

|

No. 01 Flat bed printing machine

Make: Meccanotessile

Model: A1

Width : 320 cm

With dryer chamber device A1-5M

Printing area length : 18 m

8 Colours

Maximum heald frames : 11

Printing ratio :75 cm

Can print Sari

Totally reconditioned in 2003

belt replaced in 2003

|

|

#42.226 #42.226 |

|

No. 02 Embroidery machines

Make: COMERIO Ercole

Model: CE 15/108N

Year: 1982

max embroidery ratio: 108/4

max work lenght: 15 yards

Serial nos: 388, 366

Machines have been modified as follows:

addition of electronic equipment cascafili model CF4

01 machine with full electronic modification made by BIESSE

01 machine with the capacity to read drawings on floppy disk from a PC instead of reading drawings from cardboard

|

|

#42.190 #42.190 |

|

NO. 01 Twisting machine

Make: Volkmann Saurer

Model: VTS05

130 spindles with travelling cleaner

Year 2000

Machine in running condition

working on wool carpet yarn

No. 01 Twisting machine

Make: Volkmann Saurer

Model: VTS05

130 spindles

Year 2003

Complete

|

|

#42.073 #42.073 |

|

NO. 01 SECTIONAL WARPING MACHINE

Make: Benninger

Model: Ergotronic

2500 mm

Year: 1995

Sectional warping

Electronic control

Fixed cone 3070 mm

With Benninger reed

With Bennigner creel of 384 ends

|

|

#42.070 |

|

No. 03 TWISTING MACHINES

MODEL: VTS 08, TM 21.05753,

Year: 1989:

156 spindels

feeding package: 6" or 7", pre assembled

twisted package: 6", actually 4º20'

wax device

traverse changing for the production of soft bobbins

pote diameter of 165 mm

excellent conditions

pictures attached

Construction serie 4

No. 02 TWISTING MACHINES

Model: VTS 09-0 TM 21.07113,

Year: 1996,

160 spindels

feeding package: 6", pre assembled

twisted package: 6", actually 4º20'

traverse changing for the production of soft bobbins

transport band for full bobbins and empty bobbins reserve

excellent conditions

pictures attached

Construction serie 6

No. 02 TWISTING MACHINES

Model: VTS-09-0 TM 21.07956,

Year: 2001,

192 spindels

feeding package: 6", pre assembled

twisted package: 6", actually 4º20'

wax device

transport band for full bobbins and empty bobbins reserve

traverse changing for the production of soft bobbins

excellent conditions

Construction serie 6

No. 02 Deing Vessels

Make Obermaier

loose stock/package dyeing vessels

750 / 1000kg capacity each

No. 01 Dryer for Fibre Radio Frequency type

Make Strayfield

RF drying line for loose stock

c/w Rousselet hydro.

and Pneumatic conveyor material transfer

|

|

#42.064 #42.064 |

|

n. 19 automatic coner machines

Schlafhorst Oerlikon

Model 338 V

N. 20 spindles each machine

Electronic clearer Uster UQC2 IMK C15-F23

Traverse 4”

Conicity soleil

With Variopack

With Propack

Thermosplicer

Autotense FX

With C.T.S.

With tubes cleaner

With second cops preparatory

Spindle identify

|

|

#42.061 #42.061 |

|

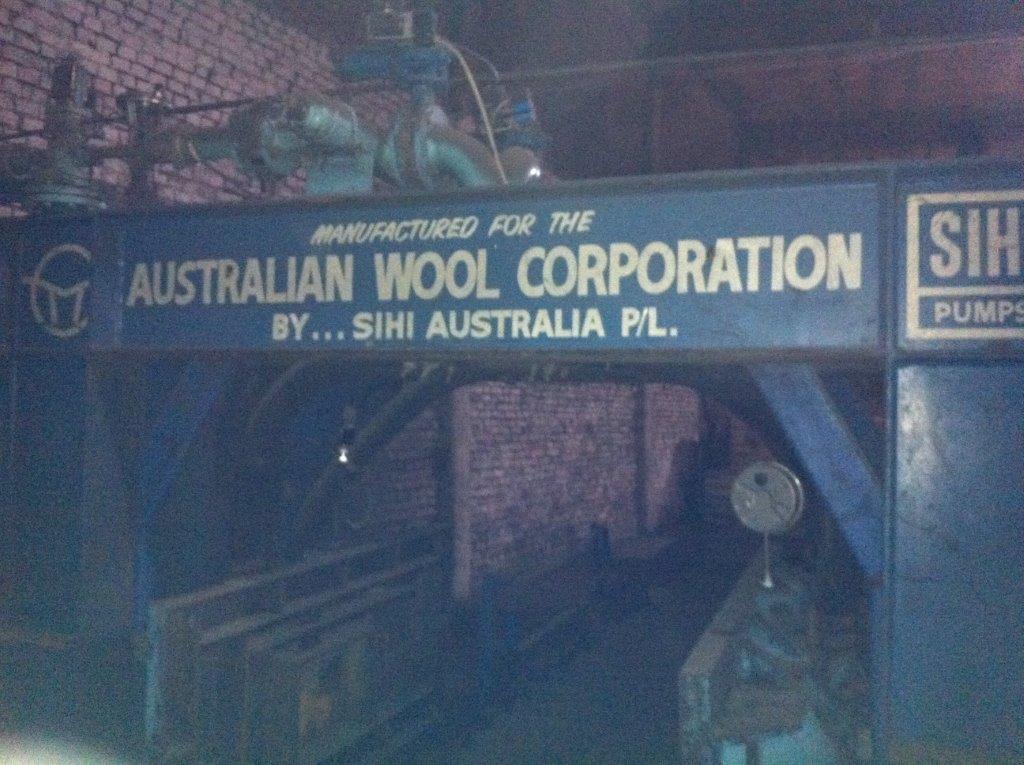

N0. 1 FORCED CONVECTON BALE WARMER

MAKE SIHI – Australia

YEAR 1988

Complete with one set of infeed and outfeed conveyors

Total length 21.000 mm

Machine used to warm wool bales received from maker to start washing and combing process. Wool bales arrives from producer very pressed and compacted. With this machine bales are heated and lanolin is partially dissolved to allow the washing process.

|

|

#42.052 #42.052 |

|

No. 34 Second hand Airjet looms

Make: PICANOL

Model: OMNI 190-2-R

Width 190 cm

2 colours

22 mcs of year 1999

with electronic dobby Staubli 2580-C with 16 levers

12 mcs of year 1995

with electronic dobby Staubli 2580-RS with 12 levers

with inspection table

with leno

Each machine equipped with:

2 weft feeders

1 beam flange diam. 1.000 mm

1 cloth roll

8 heald frames

5.000 heddles and droppers

|

|

#41.899 #41.899 |

|

NO. 04 Labelling machines

Make : Willy

Model: TP65 (3 MCS) 4T (1 MC)

Years: 1995 (3 MCS) 1989 (1 MC)

|

|

#41.839 #41.839 |

|

No. 4 Second hand airjet looms

Make : Tsudakoma

Model: ZAX

Width: 190 CM

Year: 1992

Cam motion

2 colours

machines equipped with :

6 heald frames

02 beams

02 cloth rolls

6.500 heddlers/droppers

|

|

#41.182 #41.182 |

|

NO. 04 Second hand looms

Make : Vamatex

Model: Leonardo

Width : 210 cm

Year: 1998

8 colors

With Fimtessile Dobby model RD840/S 20 shafts

(not all installed )

Each machine equipped with :

1.5 beams of 1000 mm

1.5 cloth rollers

Warp stop motion 6 bars

4 prefeeders make roj Quartz ht

With Take up and let off electronic creel

7 heald frames

2500 + 2500 droppers and heddlers

|

|

#40.546 #40.546 |

|

Used WOLLEN CARDING MACHINES available immediately subject of prior sale:

N. 4 Carding Machines

Make FOR BIELLA ITALY

width of working 2500 mm

working on wool fibre or blends

year 1968 fully reconditioned in 2001

with Feeder Mechanic Weighing Balance

Entrance cylinder Diameter 400 mm

First Main Carding Cylinder Diam. 1500 mm with 5 pairs of workers and strippers

N. 1 Morel

Second Main Cylinder of carding Diam. 1500 mm with 5 pairs of workers and strippers

Combing Cylinder Diam. 1200 mm

web doffing

Sliver delivered on conveyor belt

Delivery onto 1 Intersecting MT Consult with automatic doffing type MEC of year 1997 Model CA4CF5MT with Can delivery 1000x1200mm

N. 5 Carding Machines

Make FOR BIELLA ITALY

width of working 2500 mm

working on wool fibre or blends

year 1964 fully reconditioned on 2001 (4 mcs)

year 1972 fully reconditioned on 2001 (1 mc)

with volumetric Weighing Balance feeder

Entrance cylinder Diameter 400 mm

First Main Carding Cylinder Diam. 1500 mm with 5 pairs of workers and strippers

N. 1 Morel

Second Main Cylinder of carding Diam. 1500 mm with 5 pairs of workers and strippers

Combing Cylinder Diam. 1200 mm

web doffing

Sliver delivered on conveyor belt

Delivery onto 1 Intersecting MT Consult with automatic doffing type MEC of year 1997 Model CA4CF5MT with Can delivery 1000x1200mm

|

.jpg)

|

#39.568 #39.568 |

|

EXCEPTIONALLY LARGE LOOM TO MAKE SPECIAL INDUSTRIAL FABRIC OF WIDE 10 METERS ON SALE

NO.2 Sulzer Projectile looms extra large loom

type TW11 426" ES 110 E10 D2

Single colour, cam motion E10/4, with batching motions,working width 10.40 meters

with split beams

Accessories with each looms:

4 heald frames

1 batching motion

1 prewinder

4 5.000 heddles & drop wires

4 split warp beams

|

|

#38.065 #38.065 |

|

NO.12 SULZER LOOMS

MODEL P7100 B 360 N 1-1- EP D1 R

REINFORCED LOOMS

WIDTH 360 CM

WITH WEFT MIX

WITH 10 FRAMES

WITH CAM MOTION, 10 LEVERS

AUTO PICK FIND

WITH ELECTRONIC WARP LET OFF

WITH SIDE TUCK IN

WITH 2 WEFT FEEDERS IRO ORION

WITH BATCHING MOTION

WITH SIDE TUCKIN

2 WEFT FEEDERS

3 SPLIT BEAMS

WITH 8000 HEDDLES AND DROPPERS

LOOMS IN EXCELLENT RUNNING CONDITION

|

|

#33.544 #33.544 |

|

NO. 01 ELECTRONIC DOUBLING MAKE RITE MODEL ARD-L,

year 2001,

automatic doffing,

with conveyor belt,

12 heads with possibility to expand until 60 heads,

yarn break system,

wide creel.

|

.jpg)

|

#33.184 |

|

NO. 1 SECTIONAL WARPING MACHINE BENNINGER MODEL BENTRONIC

year 1998

220 cm width

flange 800 mm

electronic controls for section

cone diameter 800 mm

digital display (languages available English, Spanish, French, German)

paddle for slow movement forward/backward

max/min tension of beaming 3.00 to 0.50 KN

with 200 meters per min of beaming

automatic movement of machine

automatic leasing device

with waxing

voltage 380V 50Hz.

Without Benninger creel

Automatic tensioner

With rotary trucks

Gauge 270 mm

Electronic centering

480 cones

|

|

#33.061 #33.061 |

|

NO. 3 CARDING MACHINES MAKE MARZOLI MODEL CX400

year 1998, cotton clothing

complete with feeding Silos Marzoli B138,

year 1998.

automatic doffing.

|

|

#32.935 #32.935 |

|

NO.1 AUTOCONER SAVIO ESPERO MODEL RS

32 HEADS

YOC 1994

CLEARERS USTER QUANTUM IMK 030-F23

DOUBLE FEEDER

NO. 1 AUTOCONER SAVIO ESPERO MODEL RS

60 HEADS

YOC 1994

CLEARERS USTER UPC MK F20/23

DOUBLE FEEDER

DOUBLE DOFFING

NO. 1 AUTOCONER SAVIO ESPERO MODEL RL

60 HEADS FOR CONE TO CONE

YOC 1997

AUTOMATIC CONE FEEDING CHANGE

CLEARERS UPC MK F20/23

AUTOMATIC DOFFING

|

|

#32.911 #32.911 |

|

NO. 1 TFO TWISTING MACHINE MAKE SAVIO MODEL TDS 228

55x2 spindles

independent sides

delivery 6"

pot feed 8"

pneumatic threading

waxing

cone lift up

blower Magitex

NO. 1 DOUBLING MACHINE RITE MODEL TYPE AER/L

16 heads

delivery 8"

feeding external creel 3 ends.

|

|

#32.680 #32.680 |

|

NO. 1 FLYER NSC TYPE BM 14 (Year 1982)

64 spindles

Serial 1674

Feeding 64 cans of 700x1200 mm.

Little biberon rubber cylinder system

Bobbins delivery diam. 180 x 350 mm.

|

|

#32.641 #32.641 |

|

NO. 4 QUILTING MACHINES MECHANICAL MAKE EVALLI

width 160 cm,

60 needles,

cam design,

350 stitche/min,

production 50 mt/hour,

width 280 cm x height 280 cm x width 110 cm,

with cams, tubes and shuttles.

NO. 1 QUILTING MACHINE ELECTRONIC MECA TRANSMATIC

width 180 cm,

design insertion by keyboard,

dimensions: width 300 cm x height 280 cm x width 280 cm.

NO. 1 QUILTING MACHINE ELECTRONIC MECA TRANSMATIC

width 185 cm,

72 needles,

cam standard,

500 stitches/min,

dimensions: width 350 cm x height 250 cm x width 280 cm.

machines still erected

very simple to use

all still running

|

|

#32.179 #32.179 |

|

NO. 2 SOMET RAPIER LOOMS MODEL THEMA 11E

2 MACHINES OF 104B SERIES

WIDTH 210 CM

YEAR 1992 SERIAL 3253/3254

8 COLOUR

WITH ELECTRONIC DOBBY STAUBLI 2660 WITH 20 LEVERS ALL INSTALLED

ELECTRONIC LET OFF ON ALL MACHINES

MECHANIC TAKE UP

GFG FLOATING GUIDES

VOLTAGE 380V 50HZ

Each machine equipped with:

- n. 10 HEALD FRAMES

- n. 1 CREEL

- n. 1 WARP STOP MOTION WITH 5 BARS

- n. 4 WEFT FEEDERS ROJ QUARTZ

- n. 5000 DROPPERS AND HEDDLES

- n. 2 BEAMS

- n. 2 CLOTH ROLLS

|

|

#32.143 #32.143 |

|

NO. 2 Cone Dyeing Machine Make Pozzi

Year 1994/95

120 cones

horizontal dyeing with trolley

Optimum liquor bath ratio

Can dye even less 20 cones by closing Caps

Air cushion to save liquor bath

with Programmer Obsa.

|

|

#31.903 #31.903 |

|

NO. 1 FLYER NSC TYPE BM 12 (Year 1974)

64 spindles

Serial S6 1395

Feeding 64 cans of 700x1200 mm.

Arm and apron system

Bobbins delivery diam. 180 x 350 mm.

NO. 1 FLYER NSC TYPE BM 12 (Year 1977)

64 spindles

Serial S8 1534

Feeding 64 cans of 700x1200 mm.

Arm and apron system

Bobbins delivery diam. 180 x 350 mm

|

|

#31.900 #31.900 |

|

NO. 1 Yarn Steaming Machine Make CIMI

model year 1995

500 kg

High temp and pressure

with Control panel

was working in wool/blend yarn mill

temp 119°c max,

with Steam pressure

|

|

#31.561 #31.561 |

|

NO. 4 SAVIO WINDERS MOD. ESPERO OF 24 POSITIONS

(Year 1990)

Autoloading and autodoffing.

Mesdan splicers:

Jointair type 480 for normal yarns

Jointair type 494/1 for crepe yarns

Splicers features:

Type 480: Room 251

Oscillators S-Z

Type 494/1: Room 14S - 14Z

Oscillators S20 - Z20

Peyer P550 clearers with Inspector control

With waxing device

Delivery 6"

2,5 turns

|

|

#31.336 #31.336 |

|

NO. 12 SULZER RAPIER LOOMS MODEL G6200 W220 N 6 SP

working width 220 cm,

(1) with electronic dobby Staubli 2662 16 levers all installed year 1995,

(11) with electronic dobby Fimtessile RD830 16 levers all installed year 1996,

all looms have gear box high speed type (being looms after 1995)

12 heald frames GROB,

1,5 beam flange diam. 800 mm,

1,5 cloth rolls,

Leno selvedge,

4 weft feeders,

5.000 + 5.000 heddles and droppers,

some spares.

|

|

#31.027 #31.027 |

|

NO. 20 Rapier Looms Vamatex Model Leonardo

year 1998, width 190 cm,

8 colours

with electronic dobby Fimtessile RD 860 - 20 levers

with 3 LGL weft feeders with creel,

with electronic take up and let off,

with programmer,

with 1.5 beam and 1.5 cloth roll,

with 8 heald frames,

speed 530 rpm.

|

|

#30.787 |

|

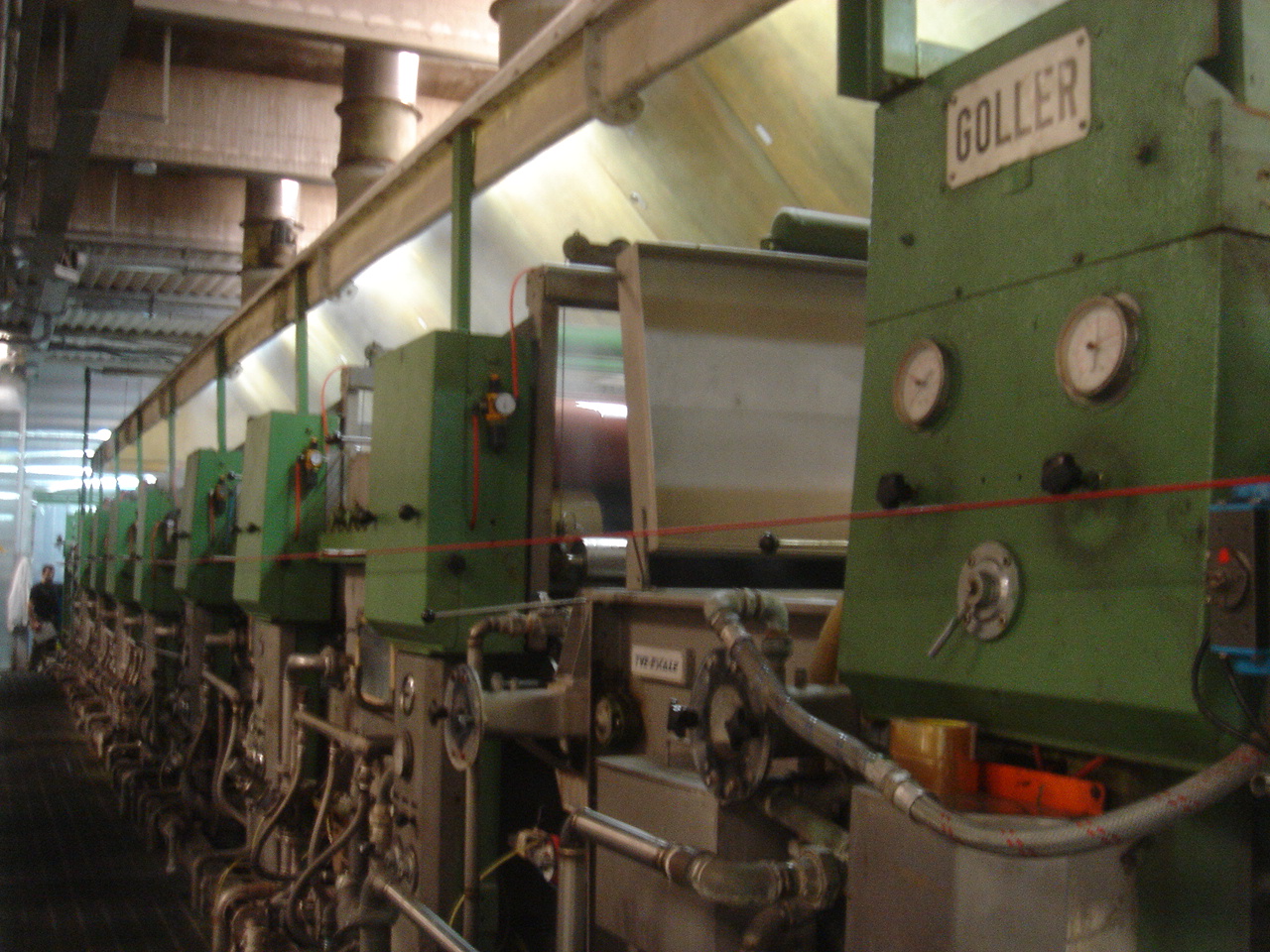

NO. 1 Washing Range Open width Make Goller

width working 2000 mm

with 9 tanks

entrance batching

with System for fabric cleaning TVE

suction

with Sqeezers each tank exit

Control Panel Termo Electronica CT 401

Heat exchangers Pozzi

Filters Beta

Year 1994

Machine running controlled thr a display and large panel

|

|

#30.673 #30.673 |

|

NO. 2 TFO TWISTING MACHINES MAKE SAVIO MODEL TDS 212,

year 1976, 200 spindles,

pot diam. 155 mm,

entry 8", delivery 6",

cone lift up,

independent heads,

with Magitex blower.

NO. 1 ASSEMBLY WINDER MAKE RITE MODEL AGR 2,

year 1986, 24 spindles,

exit 6"

independent heads.

NO. 1 ASSEMBLY WINDER MAKE SAVIO MODEL USA,

year 1976, 40 spindles,

exit 6",

independent heads.

|

|

#30.475 #30.475 |

|

NO. 6 SULZER LOOMS MODEL P7200 W 220 SP K3

year 1995, working width 220 cm,

(4) 4 colours,

(2) 6 colours,

Each machine equipped with:

electronic dobby Staubli 18 levers,

1,5 beam + 1,5 cloth roll,

16 Grob heald frames,

warp stop motion 6 bars,

complete set of projectiles and teeth guide,

4 weft feeders SaviTec with creel and electric box,

set of spares.

|

.jpg)

|

#30.418 #30.418 |

|

NO. 2 Cone to Hank Winding Machines Make Zerbo Model GX60

serial No. 4961 and 4958, year 1998,

17 hanks each side with total 34 positions,

Electronic with inverter,

speed 450 rpm,

hank max size 290 cm.

|

|

#30.340 |

|

COMPLETE HANK DYEING PLANT:

N. 2 BELLINI HANK DYEING MACHINES

For cotton and wool natural fibres

pressure 0.5 bar temp 110°c

with Two hank carrying trolleys for loading

with programmer electronic

with Two colour preparatory mixers

1415 litres

year 1987, capacity 30/40 kgs.

N. 1 BELLINI HANK DYEING MACHINE,

For cotton and wool natural fibres

pressure 0.5 bar temp 110°c

with Two hank carrying trolleys for loading

with programmer electronic

with Two colour preparatory mixers

2550litres

year 1987, capacity 70/80 kgs.

N. 1 BELLINI HANK DYEING MACHINE,

For cotton and wool natural fibres

pressure 0.5 bar temp 110°c

with Two hank carrying trolleys for loading

with programmer electronic

with Two colour preparatory mixers

3220 litres

year 1984, capacity 120/150 kgs.

complete with new programmers SATE,

all machines for pressure 0.5 temperature 110°.

All machines running

N. 2 HANK DYEING MACHINES MAKE CUBOTEX

Model 200 P/As 860-a-duomat

HANK DYEING MACHINES,

year 2001, capacity 300/350 kgs,

For cotton and wool natural fibres

pressure 0.5 bar temp 110°c

with Two hank carrying trolleys for loading

with programmer electronic

with Two colour preparatory mixers

6340 litres

almost new machines, can work in parallel.

If needed also available for drying of hanks continuously by hot air

N. 1 ALEA DRYER,

year 1988, 5 chambers,

production 700kg/h.

Full automatic turning of hanks

with two exhaust

running machine

|

|

#30.268 #30.268 |

|

NO. 7 RING SPINNING MACHINES MAKE ZINSER MODEL 420 SL,

year 1991, 1096 spindles,

ring diam. 51 mm,

gauge 75 mm,

Magitex,

tube height 260 mm.

Linked To:

NO. 7 CONE WINDING MACHINES MAKE MURATA MODEL MACH CONER E 7/2, year 1991,

34 heads, exit 6" biko,

(3) machines with clearer Peyer PI 121,

(4) machines with clearer Uster Quantum,

automatic doffing,

waxing,

Magitex,

splicer Murata.

|

|

#30.181 |

|

RAISING/SHEARING PLANT MAKE LAFER YEAR 1988 COMPOSED BY:

NO. 1 LAFER RAISING MACHINE MODE GRI-90 DUPLEX

NO. 1 LAFER RAISING MACHINE CHARDON

WORKING IN MATCH WITH

NO. 1 LAFER SHAERING MACHINE MODEL GLC

NO. 1 LAFERSHEARING MACHINES MODE C1C

working width 1900 mm.

NO. 1 LAFER SHEARING MACHINE MODEL CMS-2,

working width 1900 mm,

velveting brushes,

autmatic controller,

semiautomatic device for pile height,

microprocessor for data insertion of items.

NO. 2 LAFER SHEARING MACHINES ON LINE MODEL CMS,

working width 1900 mm, year 1994.

|

|

#30.016 |

|

NO. 1 Stenter Frame Make Santa Lucia model year 1997

width 1800 mm,

with 7 chambers,

with entrance Foulard Beta 3 cylinders,

with coating tank

with double coating,

with delivery squeezers,with

weft straigthner mech make Santa lucia

Gas Metano Heated

with entrance chain with selvedge guide

Clip type chain - (pins can be fitted -chain made for both)

Delivery Cooler

Control panel

With delivery Big batch Roll

Delivery with fabric accumulator to remove big roll without stopping machine

Two exhaust fans on chambers

With all valves and connections

380v 50hz

|

.jpg)

|

#29.761 |

|

NO. 6 OPEN END MACHINE SCHLAFHORST MODEL ACO 288 SE9,

1 machine rotor type T 236 BD, year 1996,

1 machine rotor type T 240 D, year 1996,

1 machine rotor type T 240 BNK, year 1995,

2 machines rotor type T 240 BD, year 1994-95,

1 machine rotor type T 340 BD, year 1997,

all machines SRZ type

Delivery Cone 1°20 or Cheese,

carding system S 21 DN,

knoddle KN4,

2 doffers,

bobbins changing system,

with clearer Colorab Plus.

NO. 1 OPEN END MACHINE SCHLAFHORST MODEL ACO 288 SE10,

192 heads, year 1998,

rotor type T 240 D,

Delivery Cone 1°20 or Cheese,

carding system S 21 DN,

knoddle KN4,

2 doffers,

bobbins changing system,

with clearer Colorab 7.

|

|

#29.506 #29.506 |

|

NO. 2 Hergeth sample warping machine Vertical type

model MSL 1800 MT

year 1988, working width 1800mm

10 meters warp length/multiples of 10 meters

beaming speed 800 meters per min

with beaming device

10 colours

with creel

with 4 weft feeders ROJ

with Computer programming AITA- display speed

with Pneumatic valves and end selector

working machine.

|

|

#26.116/ #26.116/ |

|

NO. 3 AUTOMATIC CONE WINDING SCHLAFHORST 238 TYPE 146,

30 spindles, automatic feeding type CBF,

output in cone 6" 4°20,

waxing device,

Leopfe TK740 clearer device,

2 lap steel drum,

autotmatic doffing,

splicer device,

with blower Magitex.

|

|

#26.116 #26.116 |

|

NO. 10 RING SPINNING FRAMES MAKE ZINSER MODEL 320,

1000 spindles, tubes of 230 mm,

ring 45,

gauge 70 mm,

draft SKF PK 235,

with roving stop fil,

with yarn sensor,

overhead clearer device,

with automatic doffing Cowemat,

year 1992/94,

speed 13.000/18.000 rpm,

length 42 meters,

10 motors of each 3 Kw,

tangential belt drive,

prodcutions average count any 30/ 550 kg per day per ring frame,

ring spinning frames suitable for synthetic and cotton blends.

|

|

#05E21GE #05E21GE |

|

We are pleased to offer you a complete lanolin extrusion line available in our warehouse.The ref letters for use in case for the layout we have attached and also you want to see photos, we can send you

Our line is composed by following parts:

n. 1 new Pump Netzsch from scouring line to lanoline line

n. 1 new fluid measurer to adjust water quantity to lanoline line

n. 1 new cyclone for land cleaning (REF. B)

n. 2 used and reconditioned Cyclones for land cleaning (REF. C AND D)

n. 2 used and reconditioned heat exchangers for steam and hot water (REF. E AND F)

n. 1 used and reconditioned tank with exit new pump (REF. G)

n. 1 used and reconditioned Centrifuge Alfalaval

model LX209

Max speed rpm 5.000

Weight 1.300 kgs

Diameter rotor 368 mm

Motor: 11 kw

1.460 rpm

500 V 50 Hz

10/17,5 A (REF. H)

n. 1 new pump from Centrifuge to Finisher (REF. L)

N. 1 Finisher Alfalaval model RUPV 407 (REF. I)

Motor: 5,5 kw

1.450 rpm

500 V 50 Hz

9,2/16 A

n. 1 new electrical cabinet to drive all machines complete with inverters (REF. M)

all connection tubes and accessories

|

|

# # |

|

LARGE CAPACITY PETRIE AND MC NAUGHT

SCOURING LINE OFFERED FOR SALE

A recognised wool scouring facility in the heartland of the wool processing City Biella, Italy, known for processing a wide range of wool microns: merino, half breed and carpet types, offer for sale their Petrie and Mc Naught. The plant is currently in operation pending sale and is available for interested parties to inspect, please, contact Prinitex, Italy, or Officina Impianti Tessili Enzo Grillo.

Phone: 0039 0434 40320

Fax: 0039 0434 538919

Email: sales@prinitex.it

|

|

# # |

|

LARGE CAPACITY A. THIBEAU

SCOURING LINE OFFERED FOR SALE

A recognised wool scouring facility in the heartland of the wool processing City Biella, Italy, known for processing a wide range of wool microns: merino, half breed and carpet types, offer for sale their A. Thibeau. The plant is currently in operation pending sale and is available for interested parties to inspect, please, contact Prinitex, Italy, or Officina Impianti Tessili Enzo Grillo.

Phone: 0039 0434 40320

Fax: 0039 0434 538919

Email: sales@prinitex.it

|

|

# |

|

No. 01 BACKWASHING LINE APT TO TREAT NO. 36 WOOL TOPS

of 20±5 gr/mt. each, Model “ LTT/4/ MADE BY COMPANY CMT-HICORP MACHINERY LTD. WITH WORKING WIDTH OF 1000 mm

MACHINE COMPOSED OF:

A) FEEDING SECTION

B) BACKWASHING SECTION

C) DRYING SECTION

D) EXIT SECTION

E) ELECTRICAL SECTION

F) CHEMICAL SECTION

G) ERECTION AND COMMISSIONING

H) GARANTEE

|

|

|